活動專區

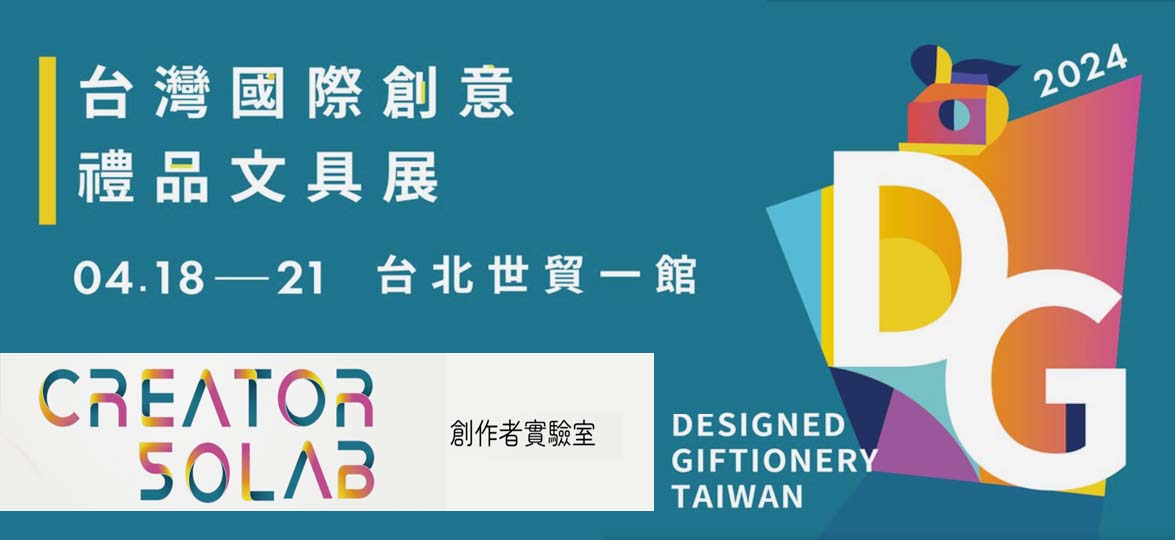

「台灣織襪工業同業公會」每年都會參與國際展覽及本地各項展售、活動等,並在多元活動後記錄伙伴的足跡,因此織襪公會誠摯邀請您加入我們的行列並攜手共創未來。

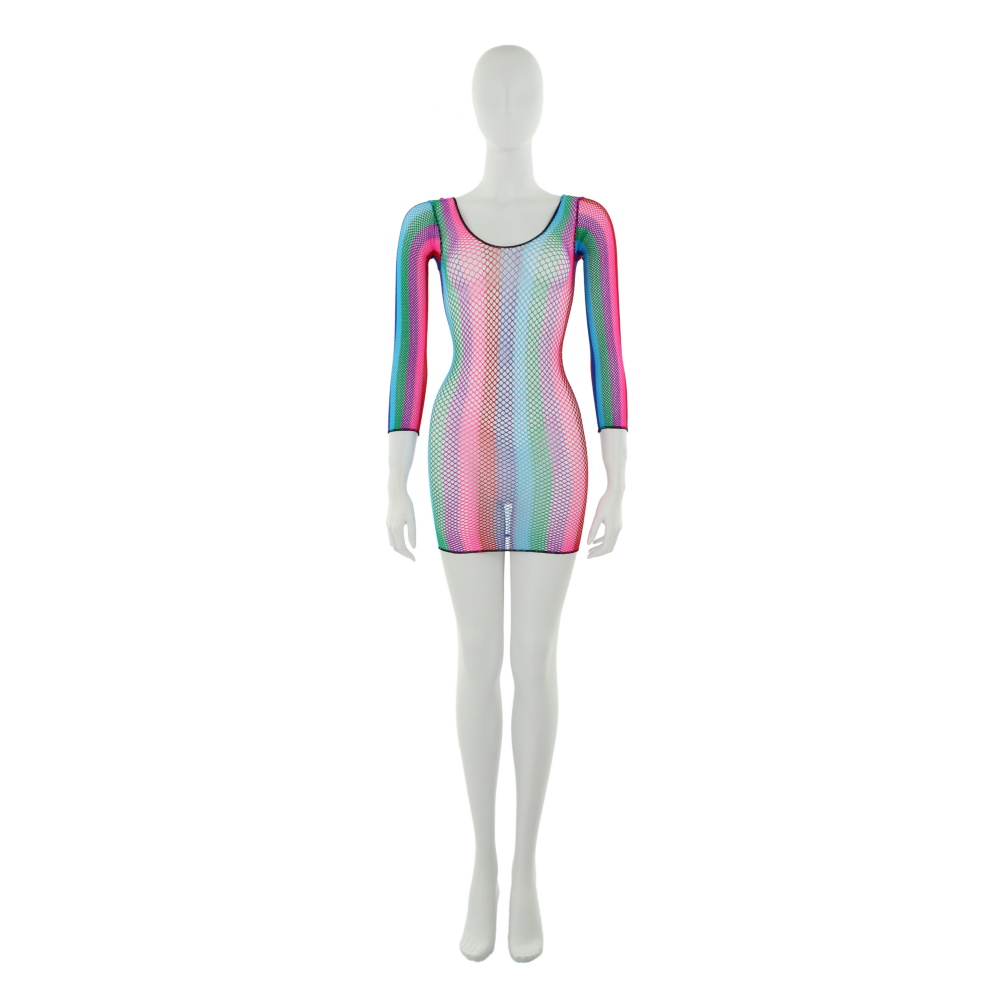

織襪公會每年都有固定的國際展覽、國內展售、好鞋好襪嘉年華活動、自強活動及會員交流等,多元活動都會增加您的企業形象曝光!

【會員專屬】

公文公告

訊息專區

公會提供第一手多元的"織襪產業"資訊,讓您迅速的掌握世界潮流資訊!

敬邀參加4月18日下午14時30分「113年台灣織襪產品全球推廣計畫」線上說明會

親愛的會員您好, 全球經濟放緩和地緣政治不確定,...

外貿協會辦理【2024年臺日商機媒合大會(0327)】免費洽談會訊息

轉發外貿協會辦理【2024年臺日商機媒合大會】免費洽談會! ...

外貿協會辦理~113年出口產品減碳包裝工作坊&1對1包裝諮詢

因應全球減碳議題,各國對於包裝及包裝廢棄物規範更趨嚴格,經濟...

113年CITD計畫~即日起至113年3月15日(五)下午5時30分59秒止受理申請,請把握時間喔!

親愛的會員您好, 經濟部產業發展署公告自即...